Project period: July 2017 - October 2017

Consultants involved: 2

Task

The objective of the project was to create Standard times and integrate them into the calculation bases.

Procedure

The project was carried out in three steps:

1st step:

Activity sampling

The objective of the study was to identify the distribution of the different activities in the areas and the separation between value-added and non-value-added activities. Another objective was to record the factual Allowance times in order to integrate them into the calculation.

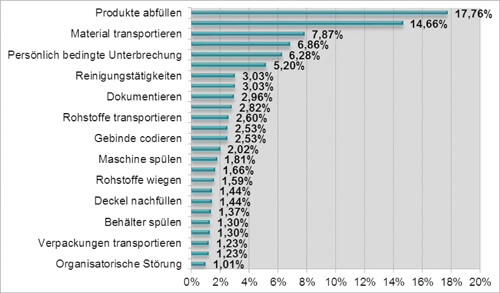

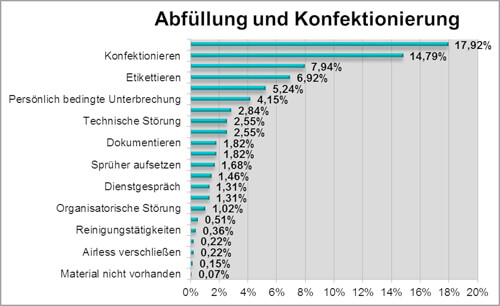

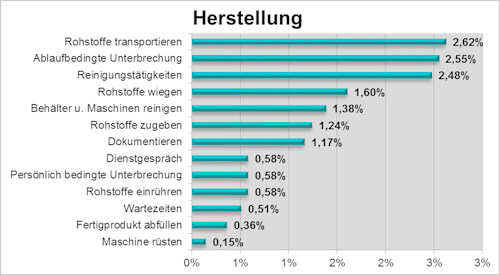

Some typical evaluations of the Activity sampling yielded the following exemplary results:

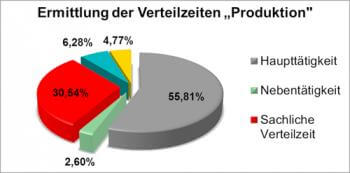

Determination of the factual allowance times

From the conducted activity samplings, the allowance times for the areas of filling, production and consignment were determined in order to subsequently be used as a basis for calculation. A differentiation was made between constant and variable allowance time.

- The factually constant allowance time (Vsk) is the sum of all times for the execution of order-independent, shift- or week-constant process segments with the process types "additional activity" and "disturbance-related interruption".

- The factually variable allowance time (Vsv) is the sum of all times for the execution of order-dependent process sections with the flow types "additional activity" and "disturbance-related interruption".

An exemplary result:

Determining the personal allowance times

The personal allowance time is made up of the sum of all times for personally caused interruptions. These interruptions consist of going to the toilet, short private conversations, hydrating and similar activities. The personal allowance time is negotiated between the contracting parties. The average in Germany is between 4 % and 5 %.

2st step: Conducting Time studies

The objective is to create Standard times. These are to be recorded for the different processes and built up in the form of standard times for calculation.

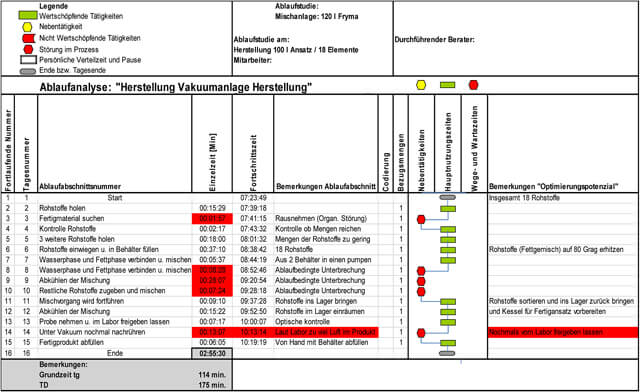

3rd step: Conducting process studies

Process studies can be used to identify unused rationalisation potential. Its systematic development improves the cost structure and product calculation.

Results

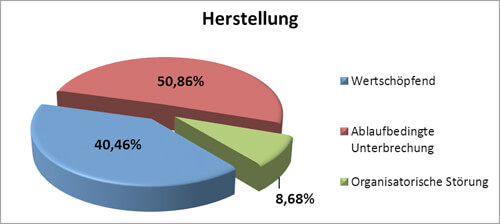

The analysis using the above-mentioned methods resulted in the following time fractions in the study area:

The following results have been found in production:

- In production, the space available is too small. This means that potential for improvement can only be tapped to a limited extent. To alleviate this situation, it would make sense to outsource some of the packing.

- The following alternative solutions could be pursued for this outsourcing:

- internal relocation to other rooms

- external relocation (e.g. a workshop for disabled people)

The expanded space can be used subsequently for process optimisation . To this end, the consultants recommend the following measures:

- Connecting coding to the filling systems

- Replacement of manual activities with lifting devices, Vibrating plate compactors and the like

- Keeping transport routes and storage spaces free to simplify handling

Bettina Dirks

Bettina Dirks